Brazing, is a metal joining process where a filler metal is used to join workpieces above 450 degrees. Unlike fusion welding, where the base metal is melted, brazing involves heating the base metal enough for the molten filler metal to adhere to it and form a strong bond.

Brazing offers several advantages, such as the ability to join different metals, less distortion or deformation of the workpieces, and a strong, reliable bond.

The metal belts are used in a wide range of applications, including the manufacturing of electronic components, cooling systems, automotive exhaust systems, and many other industries where a high-quality metal joint is required.

The metal belt is used to hold the workpieces in place during the heating and cooling process, preventing displacement or deformation.

The metal belt used for brazing should have the following characteristics:

- High-temperature resistance: Since brazing involves the application of heat, the metal mesh should be able to withstand high temperatures without deforming or releasing unwanted substances.

- Good thermal conductivity: The metal mesh should have good thermal conductivity to allow efficient heat transfer during the brazing process.

- Mechanical strength: The metal mesh should be strong and rigid enough to hold the workpieces in place without deforming or breaking during the heating and cooling process.

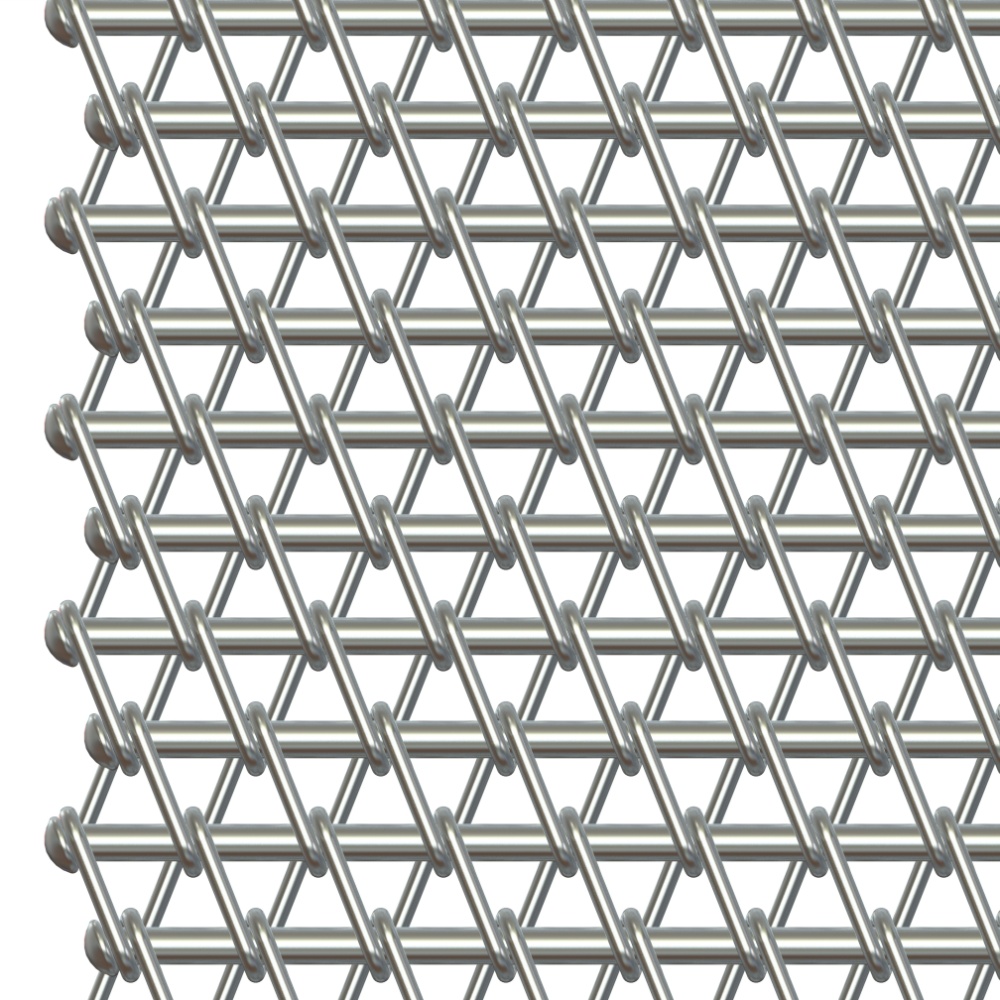

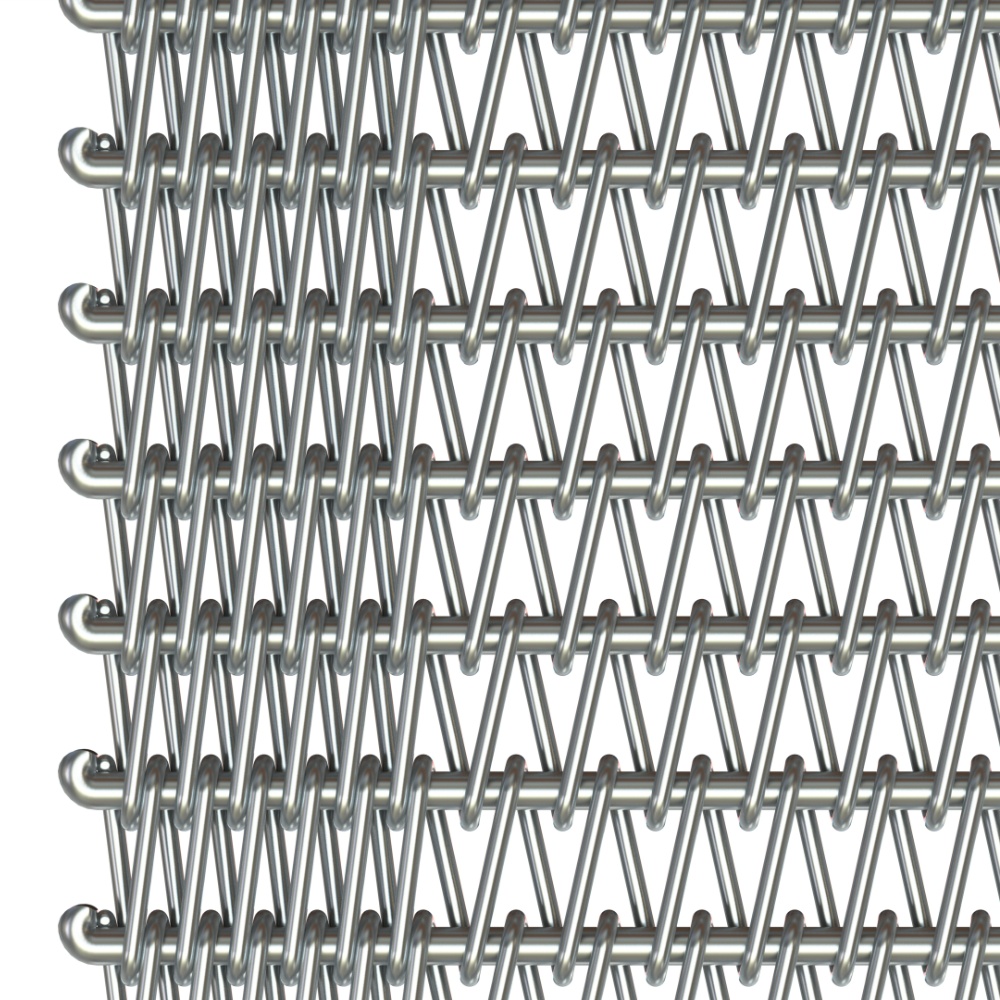

At Campbelt, we manufacture the conventional metal belt with rods (DRS) for brazing operations.. And if needed, we can add lateral reinforcements (ARR).

This belt has two key features that make it well-suited for this application:

- High tensile strength: The strong tensile structure allows for the use of a smaller wire diameter compared to other bands, achieving the same strength with less material. This helps save heat energy during the heating and cooling cycles of the installation.

- Low thermal capacity: The band has low thermal capacity, which allows for efficient heat transfer and reduces energy consumption during the brazing process.

The most commonly used materials for brazing are:

AISI 314 - Alloy widely used for temperatures up to 1150 ºC. It exhibits good mechanical properties at high temperatures, as well as resistance to oxidation and carburization, provided it is not exposed to corrosive environments in the temperature range between 700º and 900º, where it is sensitive to carbide precipitation.

AISI 330 - Alloy with a 37% nickel content and 17% chromium, with the rest of the components in proportions similar to AISI 314. In most applications, this material is more resistant to surface oxidation because it forms a thin layer of Cr and Si oxides that protect the wire when hot.

Other materials can be used according to our customers' specifications.

Choosing the right metal belt is crucial based on the process type, required temperature, and specific characteristics of the material being treated.

Contact us, and we will provide you with expert advice.