Features

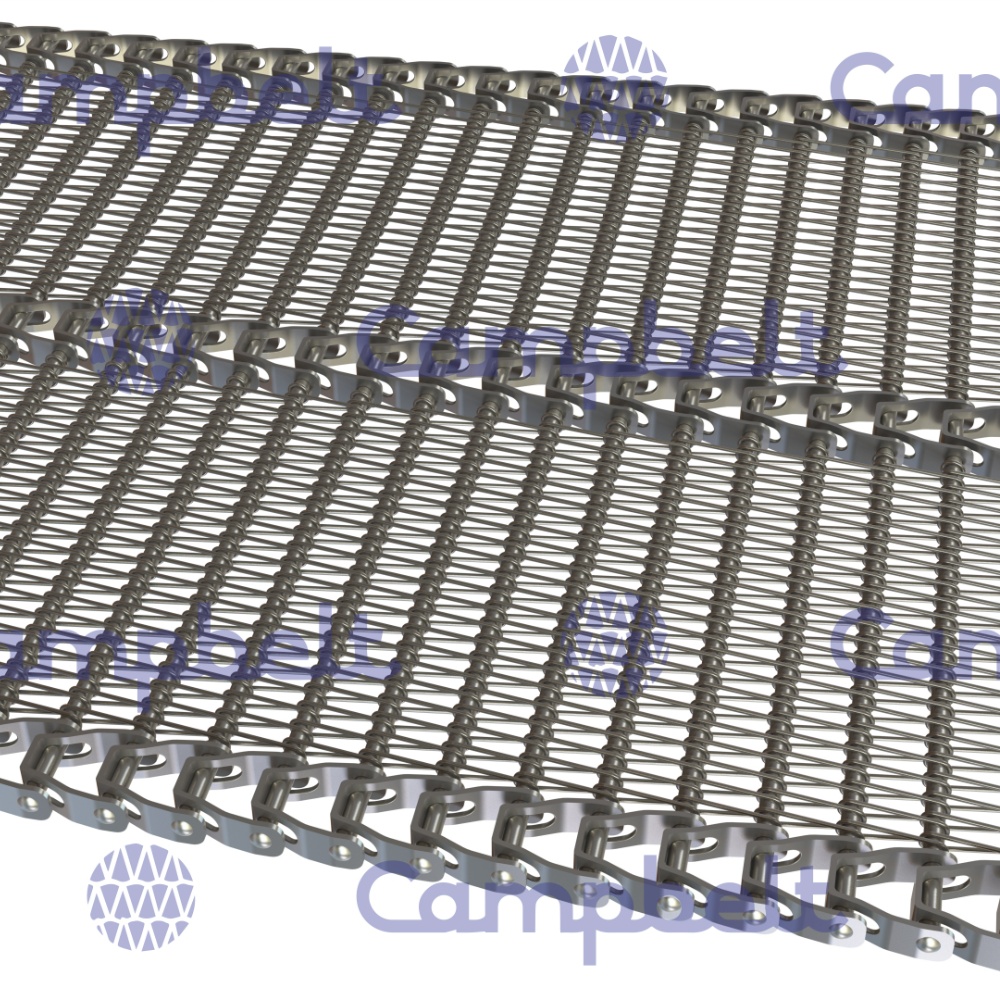

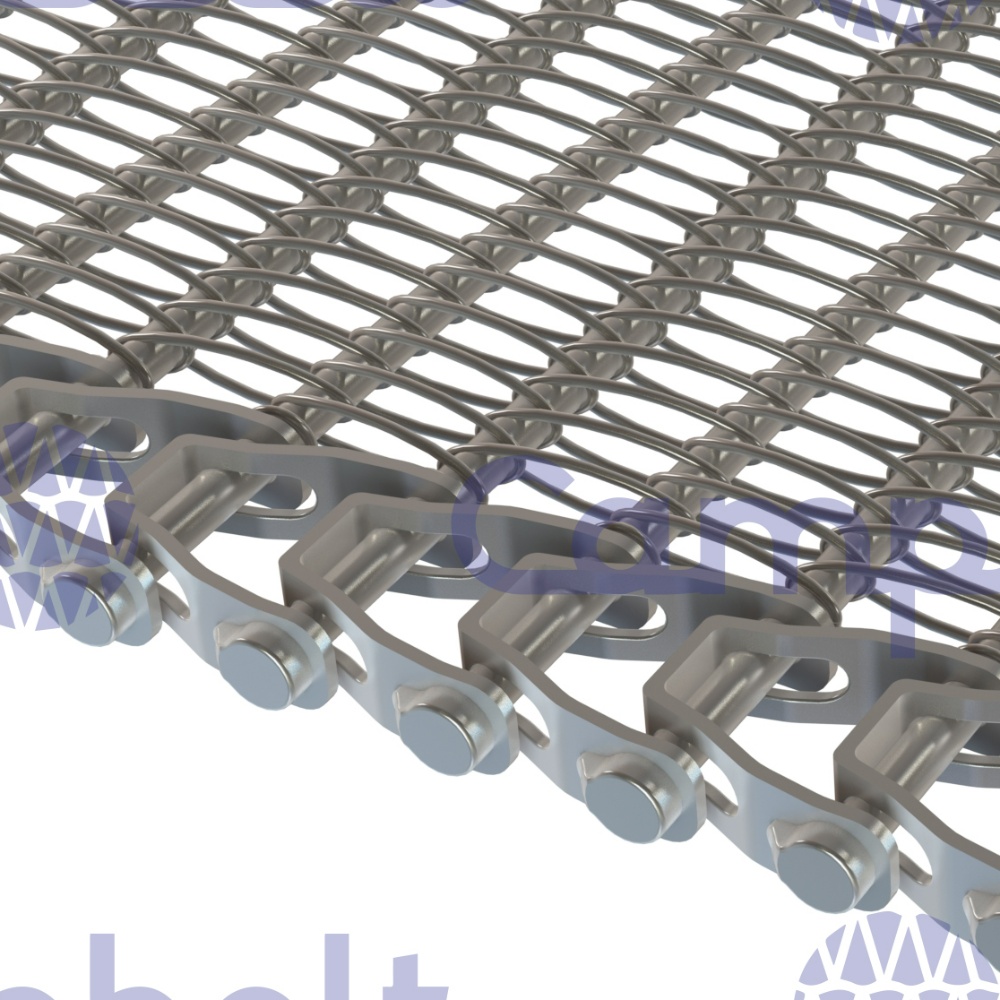

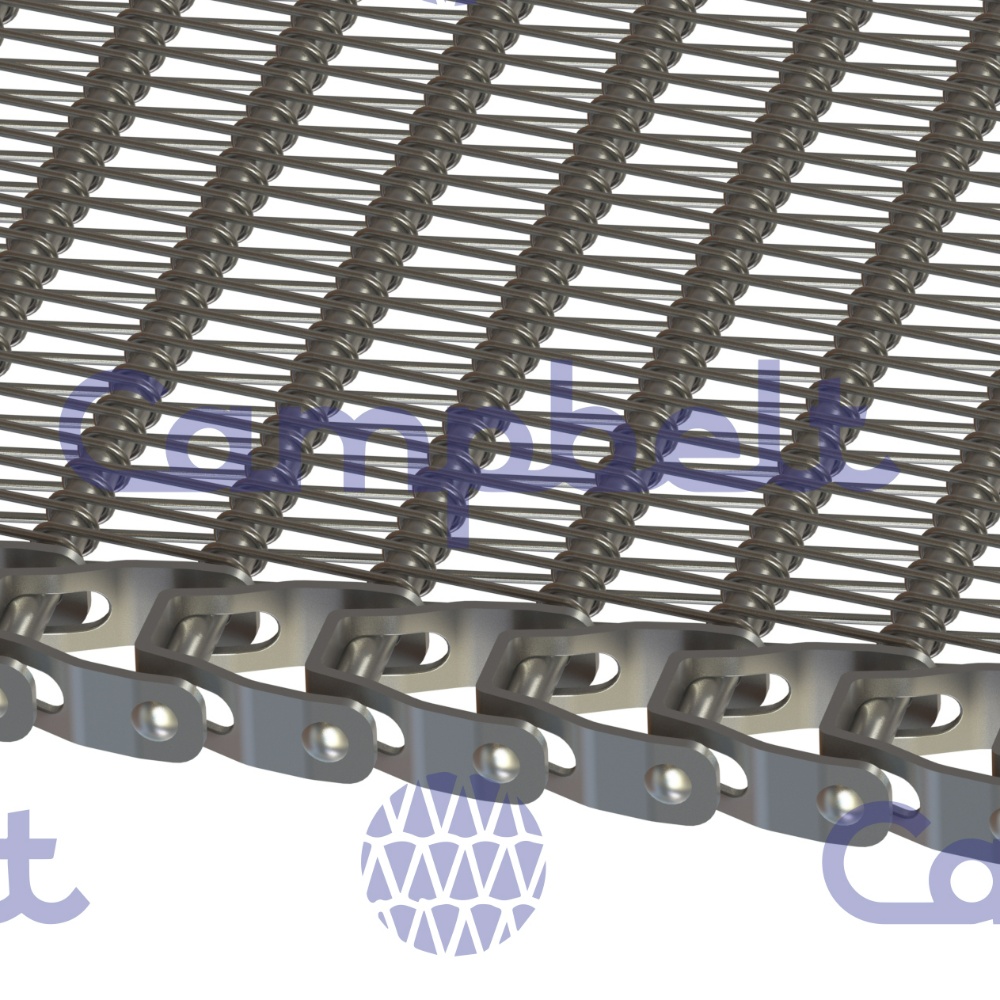

Its main feature is versatility, as it can be applied in both straight and curved sections. If required, it can incorporate mesh and/or edge guards and/or lift attachements.

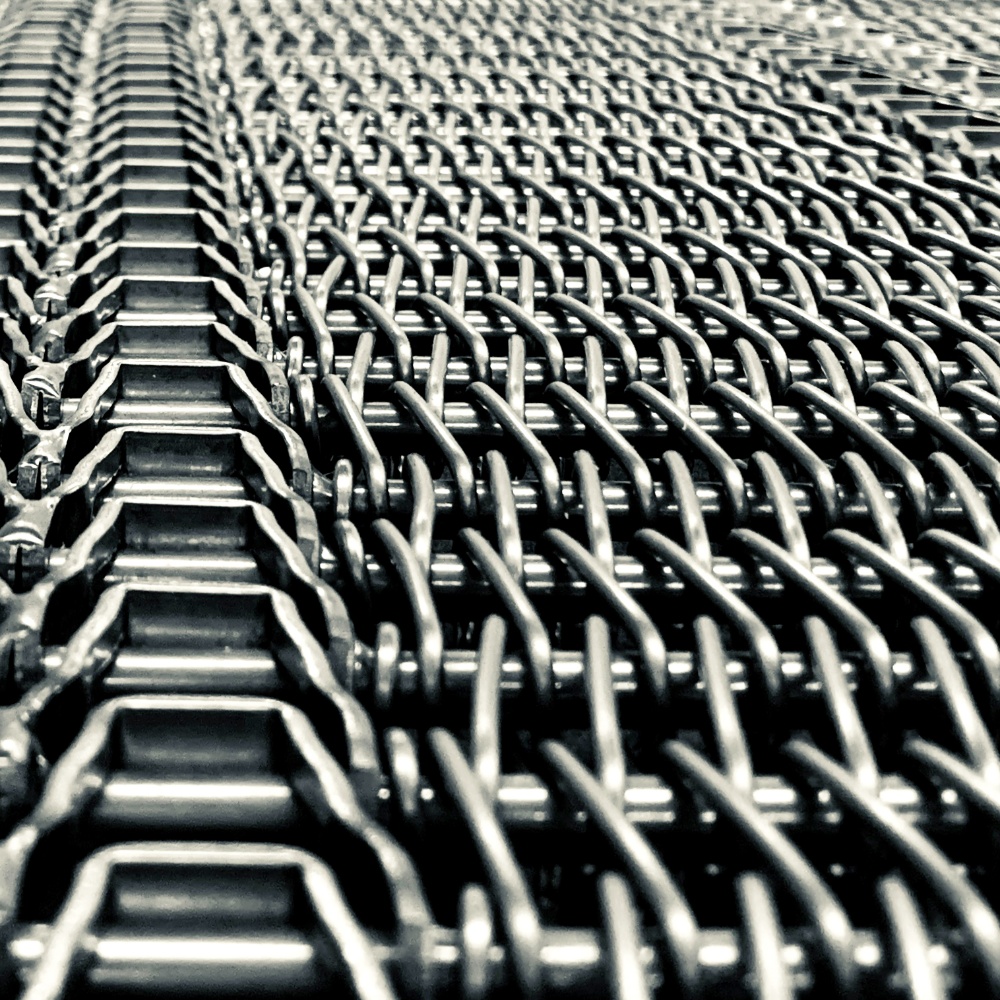

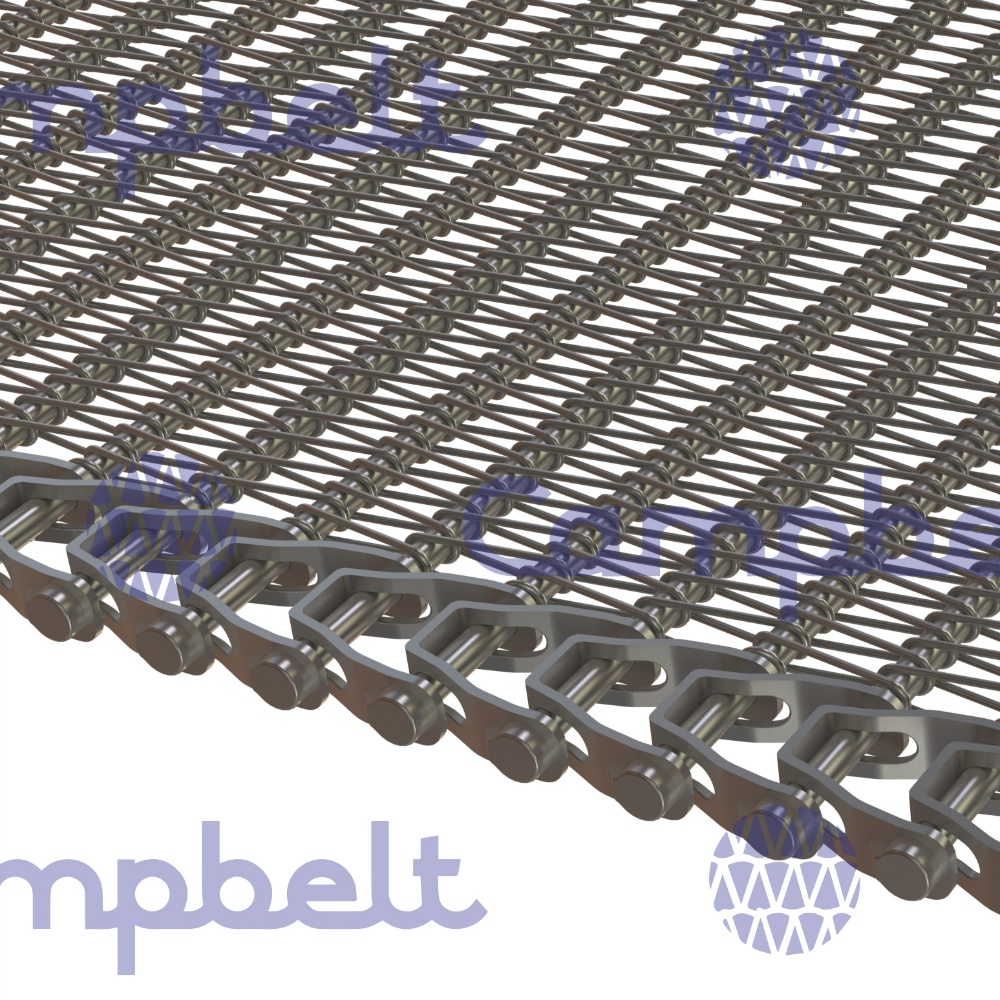

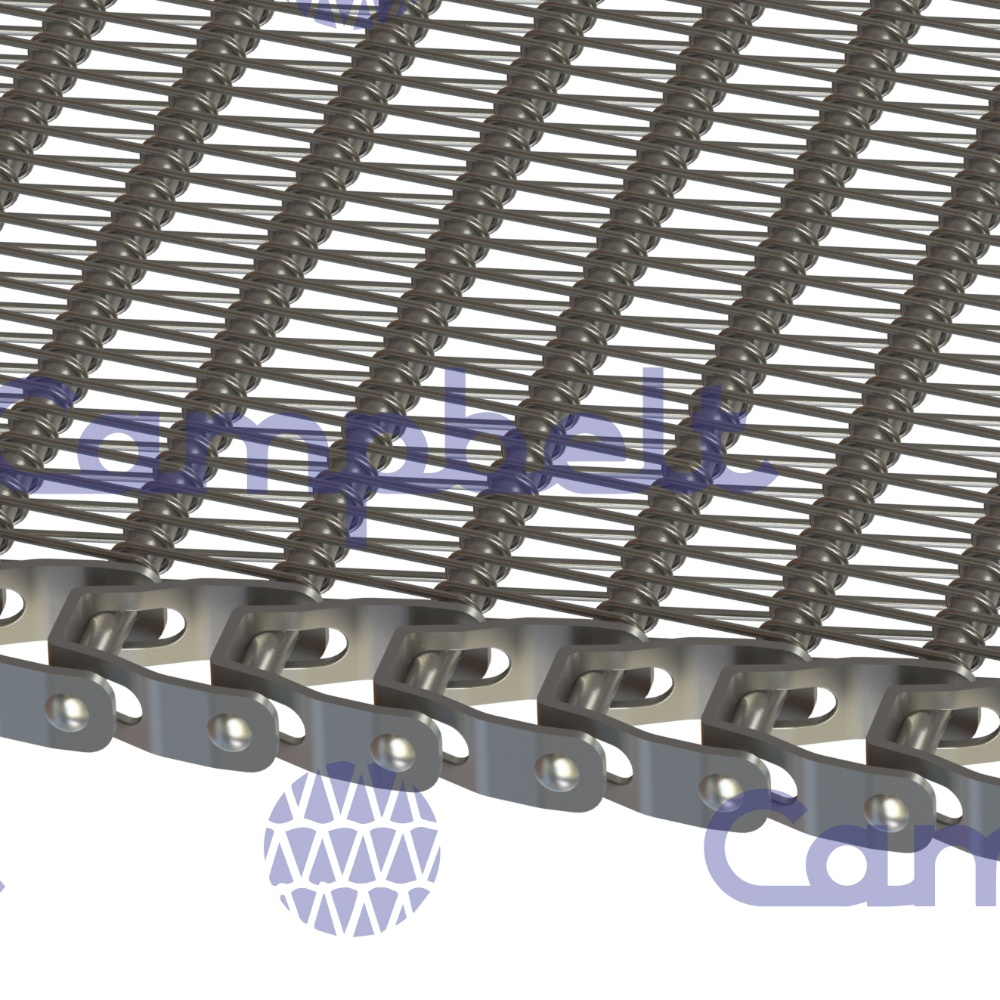

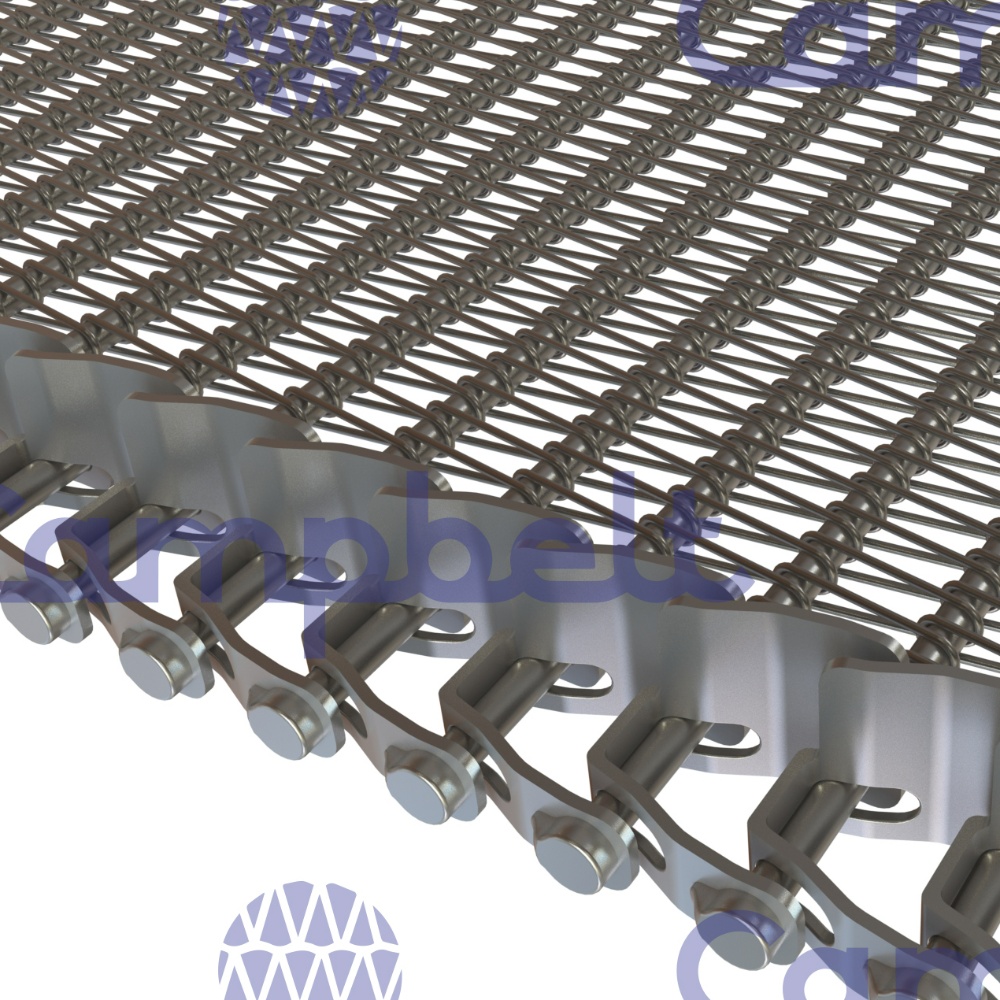

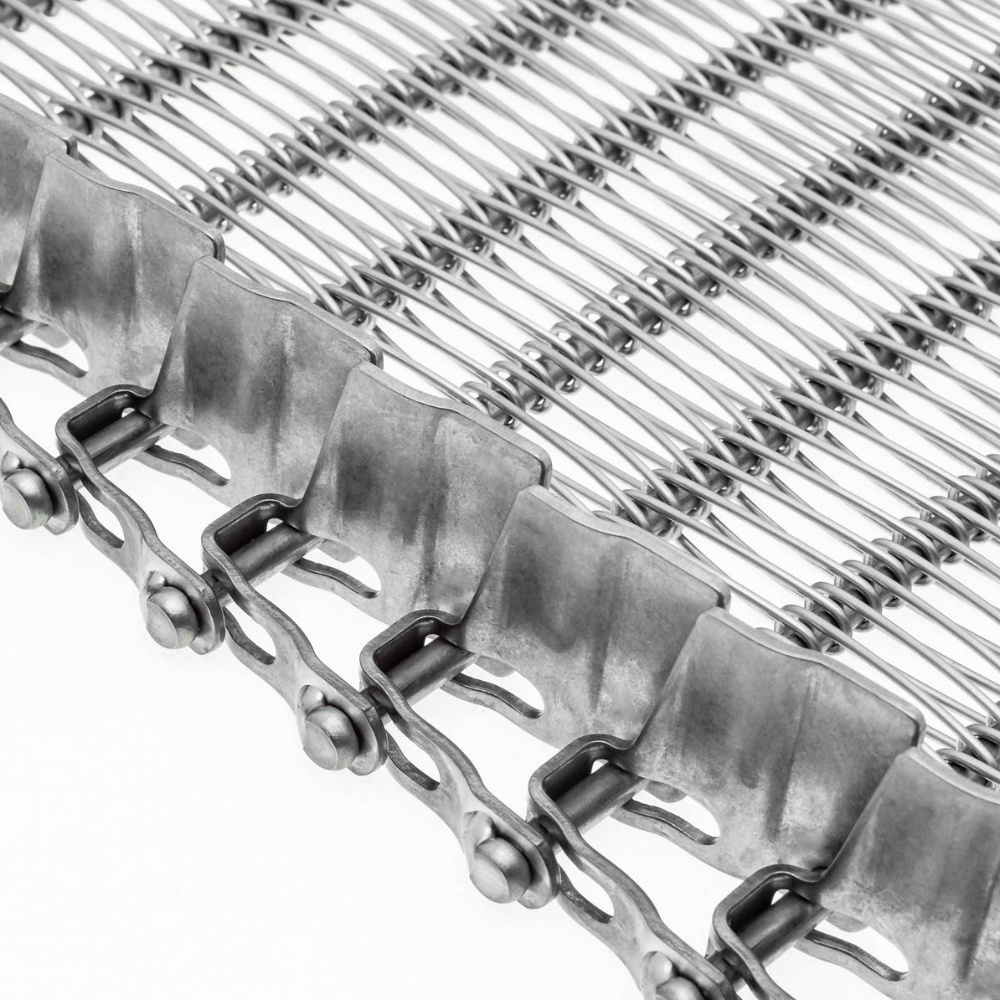

The finish on the link will depend on the type of traction the customer needs. It can be smooth; in this case, the rod is flushed and welded directly to the link (buttonless welded edge). Or with an external bump, in this case, the rod ends are upset and welded with a point to the link (welded button edge).

In the case of traction with drive shaft and sprockets, these will mesh directly with the links. In this case, the smooth lateral finish may be suitable.

However, in installations with curves and towers, where traction is provided by an inner drum, the welded button edge can facilitate traction.

In terms of hygiene, the buttonless welded edge has advantages, as it is easier to clean and disinfect, presenting fewer crevices where residues can accumulate and bacteria can proliferate.

The three standard models of link pitch are 19.05mm, 25.4mm, and 27.43mm. The turning radius will be determined by this pitch.

For widths greater than 1200mm, it is recommended to include a third central link to prevent the rods from bowing.

Materials and temperatures

They are manufactured in AISI-304-L and AISI-316-L stainless steel.

These belts are widely used in freezing and cooling processes.

Blueprints

Download spiral belt (CTA) Download spiral mesh belt with buttonless welded edge (CTA)Accessories

This metal belt can incorporate the following accessories:

Finishes

This metal belt has the following possible finishes:

Applications

They are well-known in the food industry.

They are widely used for cooling towers (pasteurization and sterilization processes).

And for freezing or ultra-freezing tunnels (ready meals, meat, fish, vegetables...).