Features

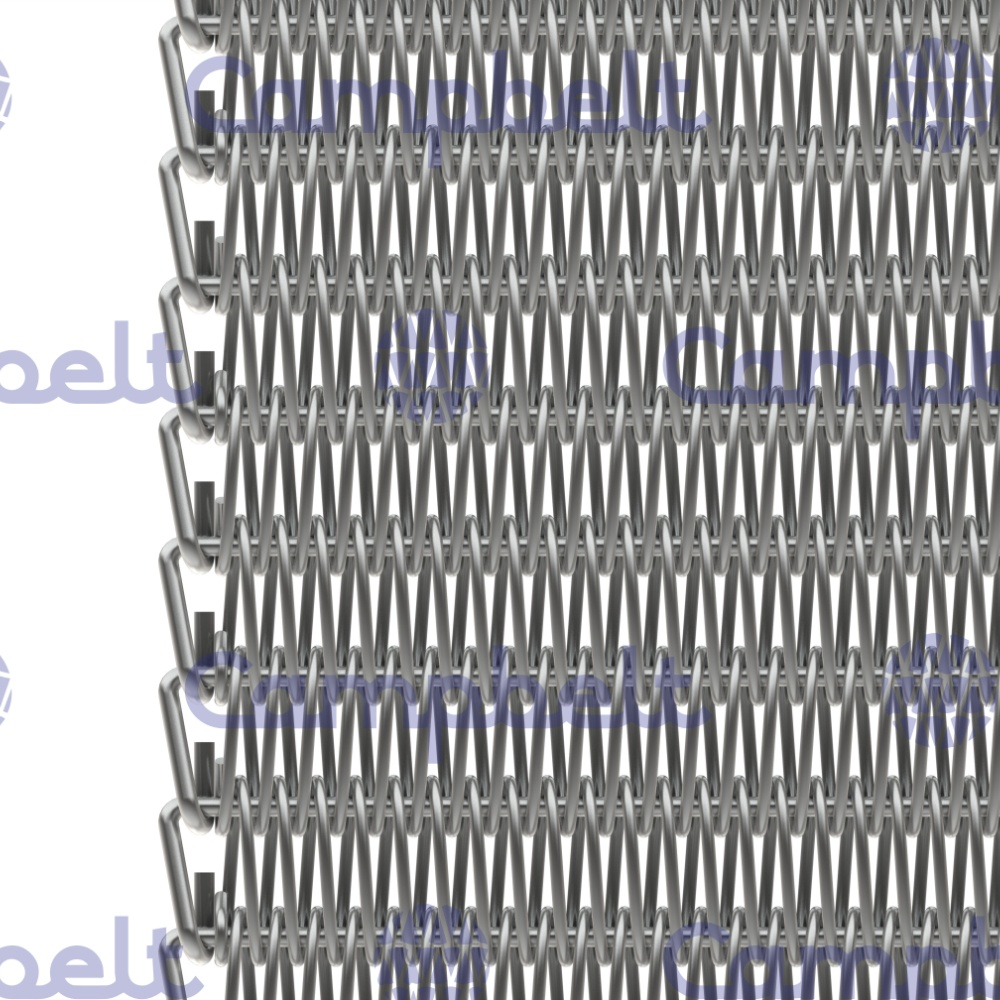

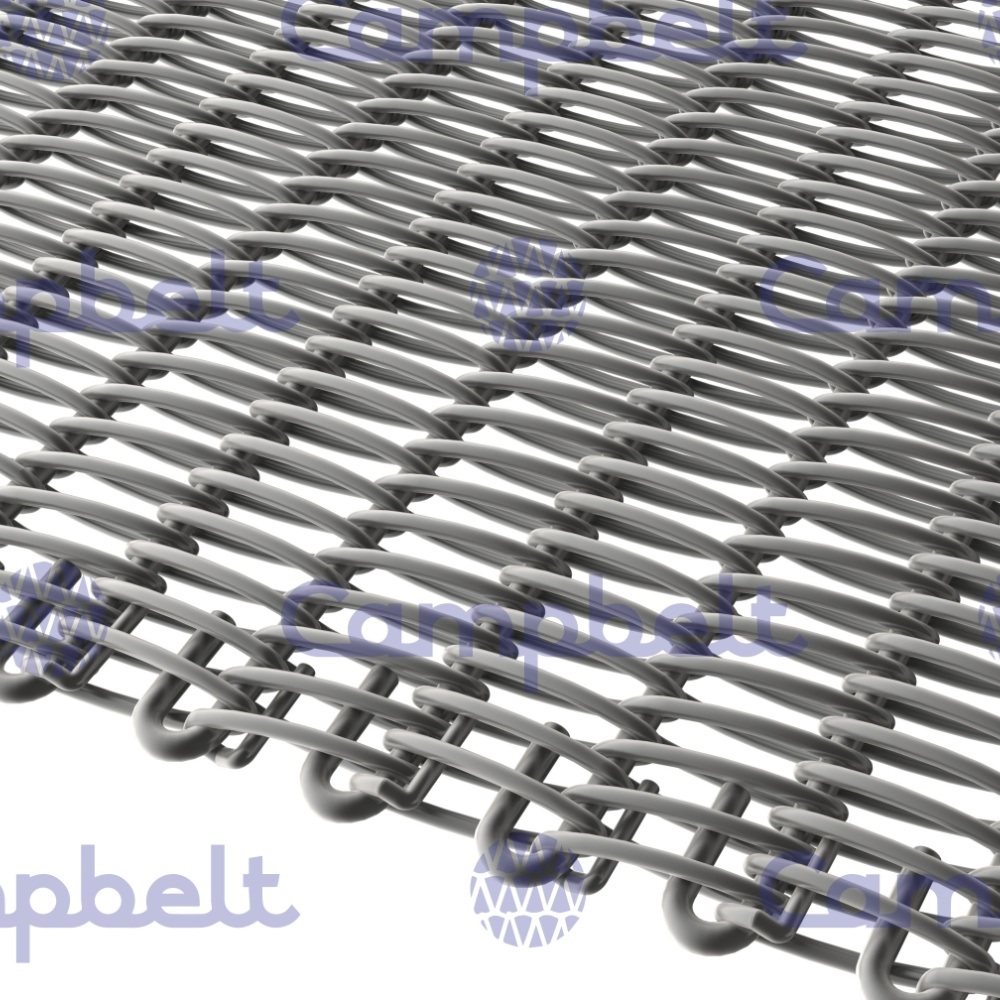

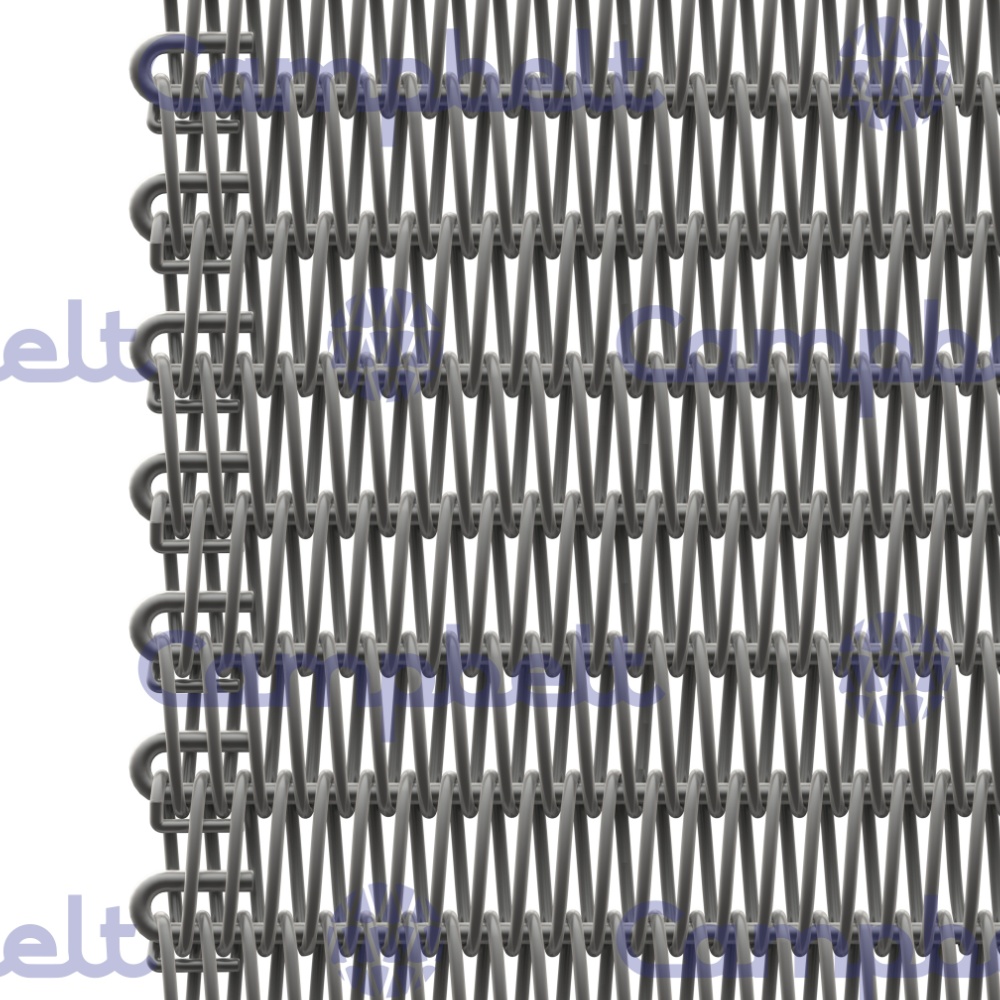

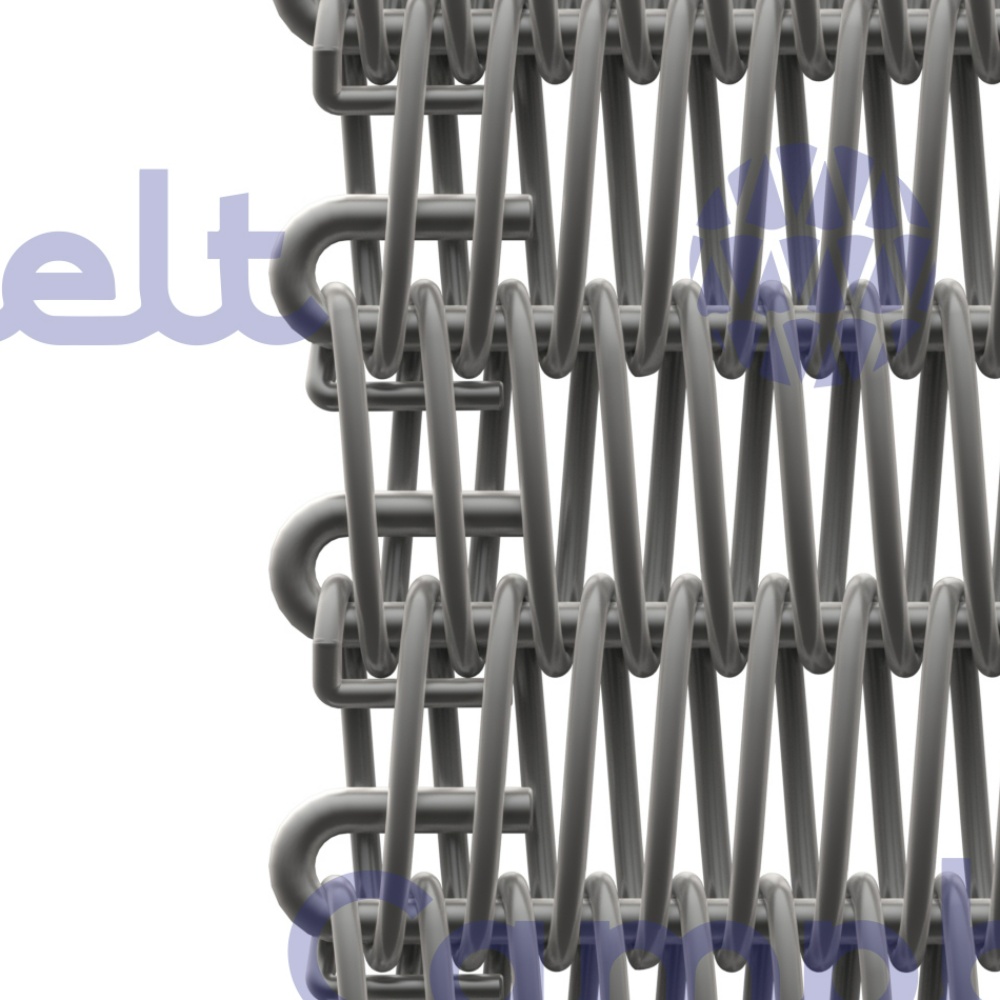

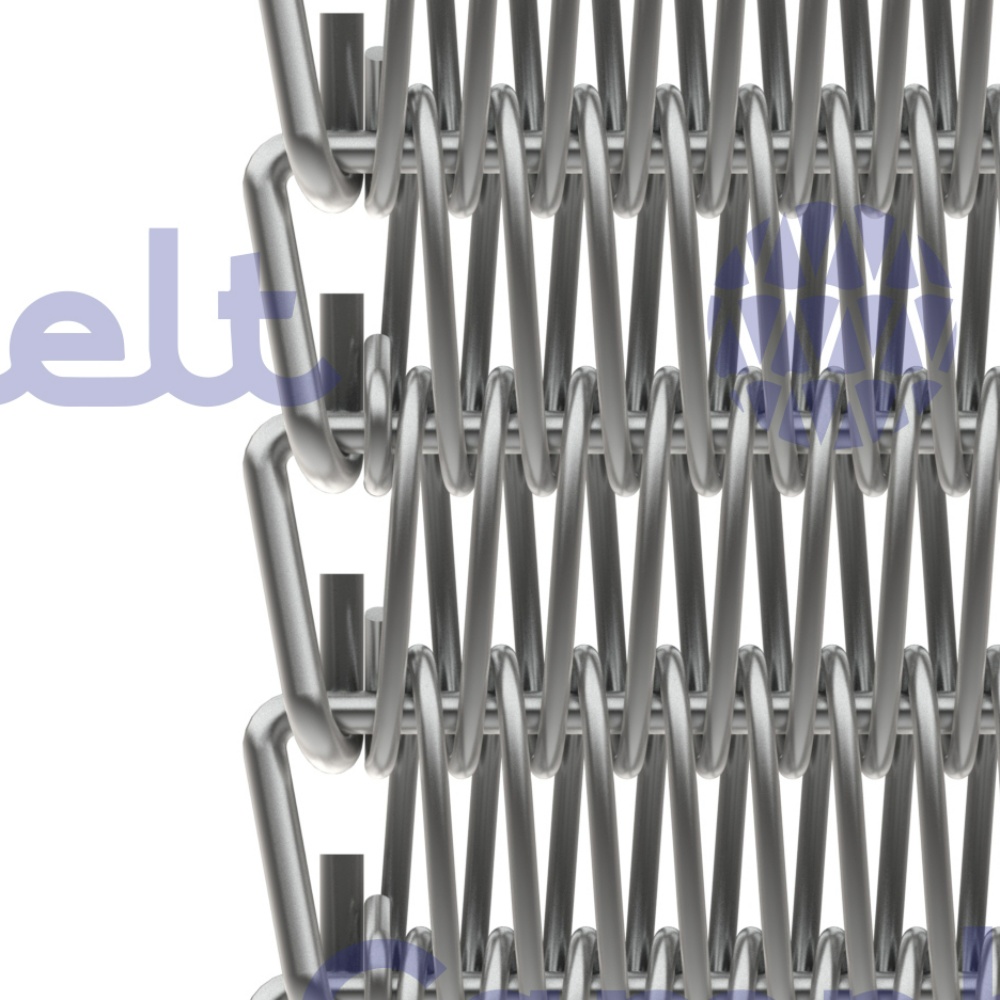

These belts can be clinched at 90 degrees (ER) or 180 degrees (ER-P).

In the case of the belt clinched at 90 degrees, the connecting rod is linked to the next one in a ladder-like fashion, forming smooth and uniform edges.

The links of the linkage can be welded to achieve greater strength.

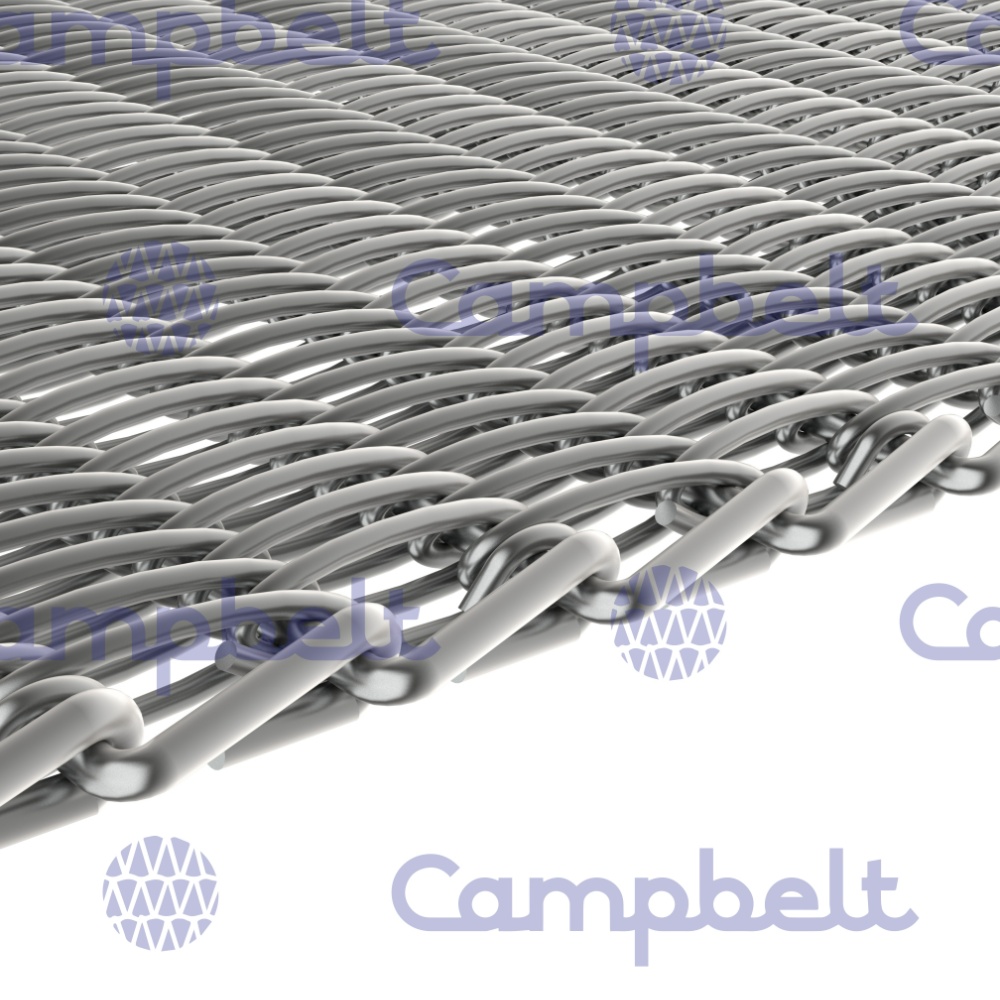

Their configuration of closely spaced spirals and clinched rods allows for a very thin and high-strength belt.

The belt clincked at 180 degrees is commonly known as the Baker's Belt. This linkage ensures controlled material stretching during the heating process, making it ideal for installation in long ovens, eliminating the potential risk of wear due to friction, thus extending the belt's lifespan.

Materials and temperatures

These metal belts can be manufactured in AISI 314 or AISI 330 (an alloy with 37% of nickel and 17% of chromium with remaining components in proportions similar to AISI 314).

These belts perform very well at high temperatures (up to 1150 degrees).

Blueprints

Download straight rod and clinched selvage belt at 180º (ER) Download straight rod and clinched selvage belt at 90º (ER)Finishes

This metal belt has the following possible finishes: