In the food industry, there is a wide variety of washing tunnels for products such as fruits, vegetables, seafood, meats, and other foods.

Metal belts are used in washing tunnels to allow water to pass through while supporting and transporting the foods as they are washed. They must comply with sanitary and food safety requirements to ensure hygiene.

These belts need to be corrosion-resistant, which is why they are always made of stainless steel. They must have an open mesh structure to allow water to pass through, ensuring effective cleaning.

Depending on the product and the characteristics of the washing tunnel, we usually manufacture three types of metal belts.

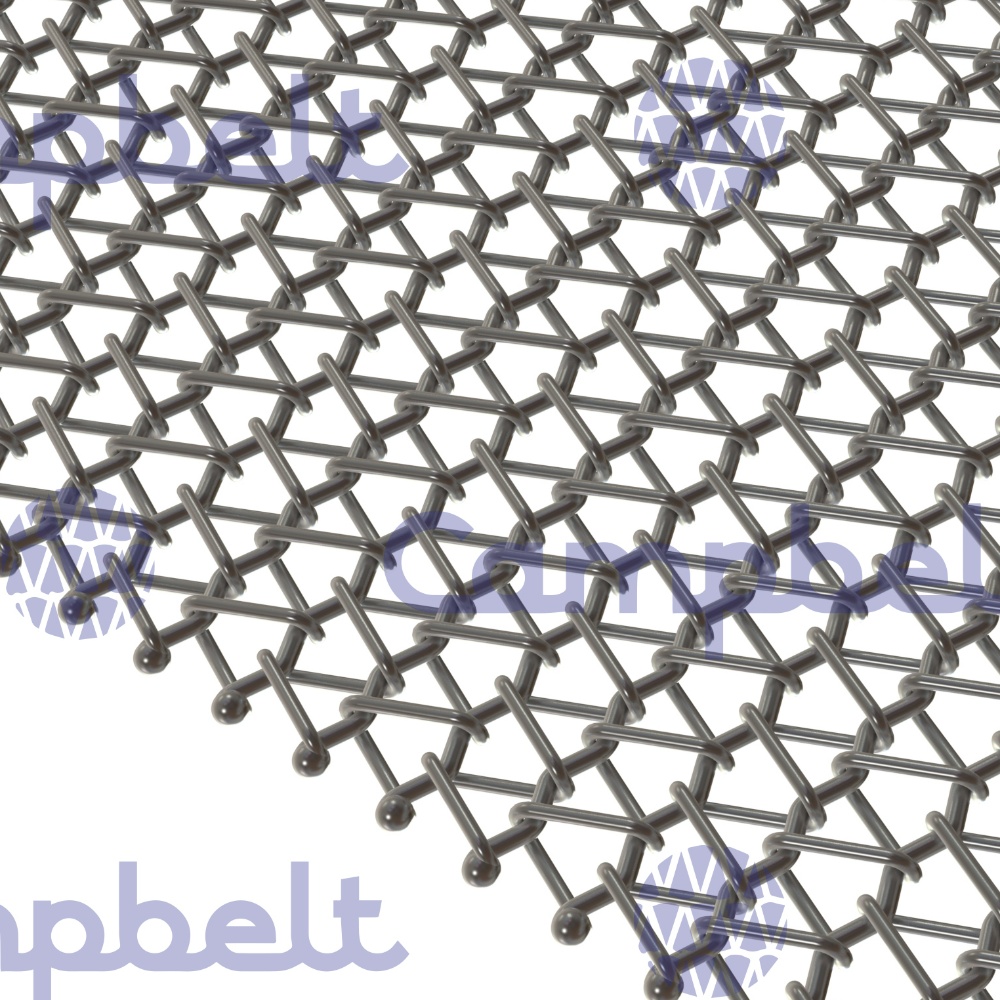

The balanced metal belt (SO) is ideal because its structure allows manufacturing with the required opening, it has an excellent strength-to-weight ratio, and it is very easy to clean.

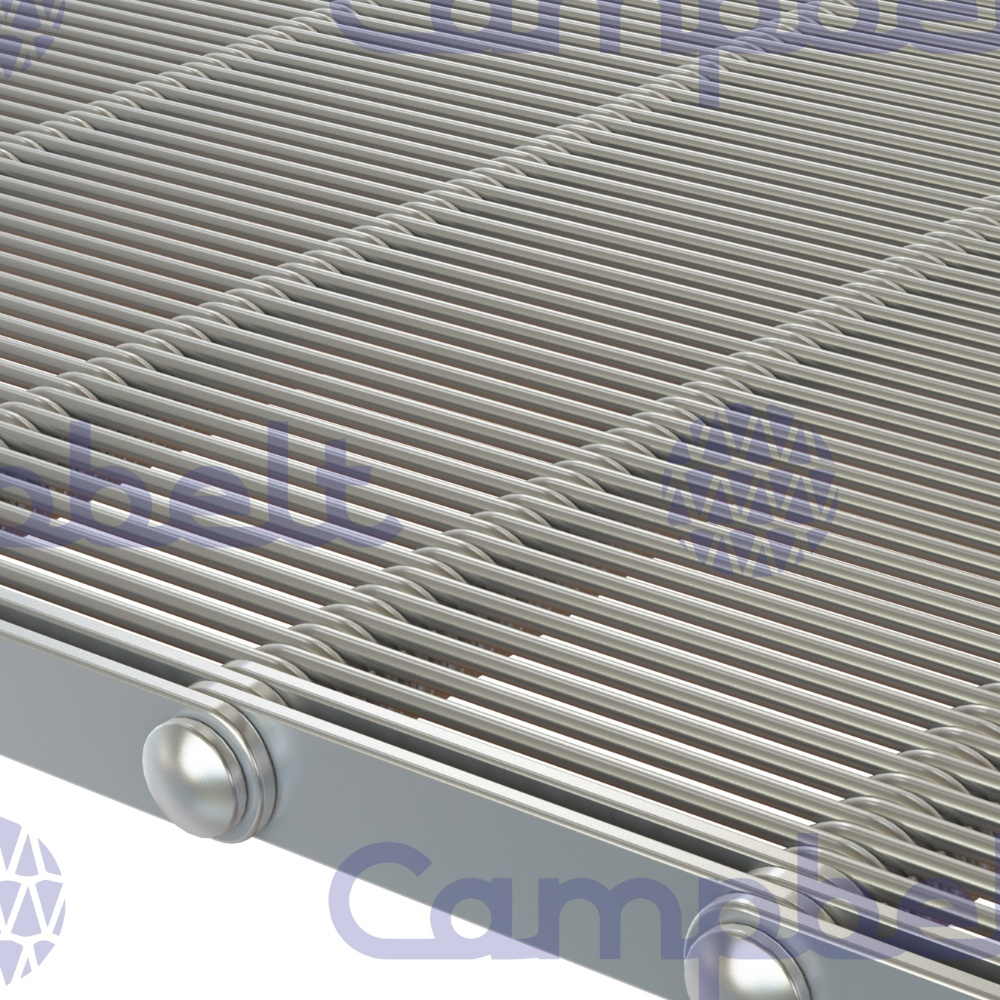

The flat metal belt (TDF) is also suitable due to its open mesh structure, which makes it very easy to clean and highly resistant.

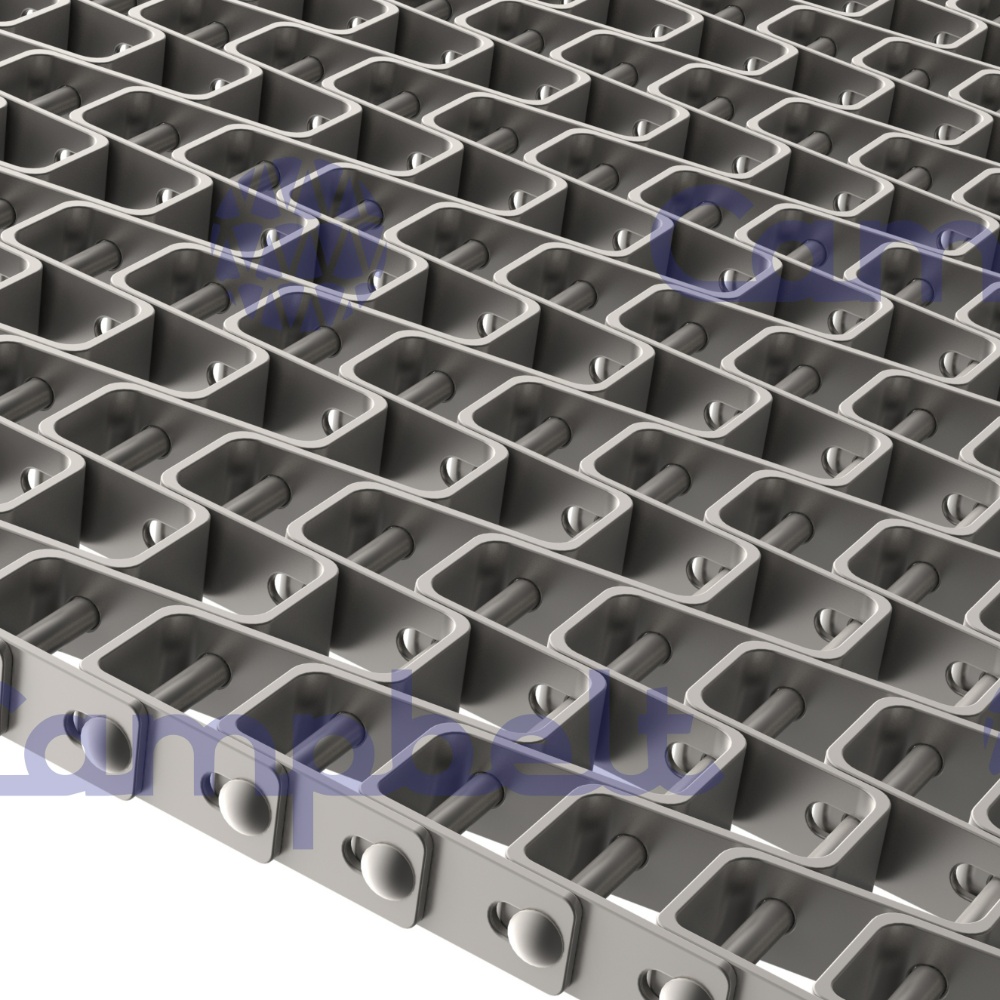

The eyelink metal belt (CMG) incorporates electro-welded rods to create a more open yet strong surface. It is also easy to clean and less prone to obstruction.

If you need a belt for a washing tunnel, please contact us, and we will help you choose the belt and the material that best suits your needs."